Aluminum nitride is a high thermal conductivity ceramic powder that shows excellent thermal conductivity, insulation properties, mechanical strength, and a coefficient of thermal expansion compatible with silicon and SiC. Therefore, it is commonly used in various high thermal conductivity insulation applications, such as IGBT modules for rail transportation, heat sinks for optical modules, and components for semiconductor equipment like wafer heater and electrostatic chucks.

The main production methods for aluminum nitride powder are as follows:

1.Carbothermal reduction method

2.Direct nitridation of aluminum powder

3.Self-propagating high-temperature synthesis

4.Chemical vapor deposition

Among these, the carbothermal reduction method and direct nitridation of aluminum powder are currently the mainstream production methods. Their advantages and disadvantages are compared below:

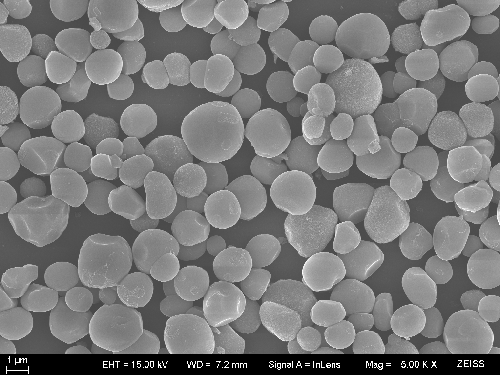

Advantages of the Carbothermal Reduction Method:

1.Wide availability of raw materials

2.High purity of synthesized powder

3.Small particle size with a narrow particle size distribution

4.Near-spherical morphology

5.High sintering activity

Disadvantages:

1.High reaction temperature

2.Long reaction time

3.Control of carbon and oxygen content

4.High production costs

<SEM of AlN powder produced by carbothermal reduction method>

Advantages of the Direct Nitridation Method:

1.Low raw material cost

2.Low energy consumption for synthesis

3.Short synthesis time

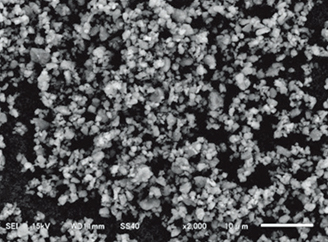

Disadvantages:

1.Agglomeration of powder

2.Requires a grinding process

3.Irregular powder morphology

4.Wide particle size distribution

<SEM of AlN powder produced by direct nitridation method>

Currently, Xiamen Juci uses the carbothermal reduction method to produce aluminum nitride powder, with a production capacity of 700 tons per year at the Xiamen factory and 1200 tons per year at the Inner Mongolia factory.

Contact:

Xiamen Juci Technology Co., Ltd.

Phone: +86 592 7080230

Email: chenxiaofang@chinajuci.com

Website: www.jucialnglobal.com